After carefully taking down the loose warp with reed, wrapping it in the short pieces of wood, I installed the reed, wrapped the various warp stripes across the front beam, and begin to sley the heddles. It was a weekend project to sley the heddles. It was really cool to see the wound-up warp tightened on the front beam.

I found online a cool technique to spread the warp. Basically, I used some junk yarn, doubled up, and WITHOUT using the beater put four rows of tabby loosely spaced, then gently pulled the beater bar and placed the warp. I then tabbied about an inch of the tea stained warp and hemmed stitched the beginning. The ends were going to be hemmed later but I wanted to give myself the option of a no-sew hem. As it turned out, I ended up hand stitching the hem later.

This was my first wide warp. I learned that my floor loom beater was not properly adjusted. When I first started to throw the shuttle, it went everywhere! The floor, popped out the top, I was like a crazy person on the batting field hitting backwards flyers! I happened to come across a picture of a LeClerc loom, looking for pictures of shuttles. I thought the shuttle was the problem! I noticed that the beater bar sat right at the level of the threads. Not mine! There was a huge space between the threads and the bottom of the beater and heddle. The threads were trying to take the weight of the shuttle. Combine that with the force of a throw, and you end up with a shuttle flying off the trampoline of threads! OMG! The beater had a height adjustment! Who knew! The beater was never set properly! No wonder I had so much trouble throwing my shuttle. After correcting all of that, it was a dream!

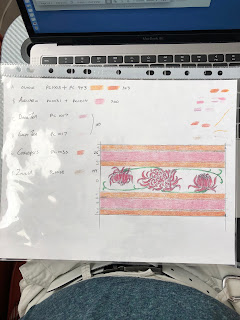

I really really loved the tea stained weft across the various hues of the natural colored warp. The dark brown weft does show up the pattern more, but I would not change color next time. It wasn’t for lack of research. Many online sources suggested a darker weft to show up a painted warp. And, yes, lest you already think it, swatch, swatch, and swatch. I do force myself to knit up a swatch first on a knit or crochet project. I do a little hand-stitched swatch for weaving to test the set. But, I haven’t been able to muster the patience of warping and doing a loom sample. Seems like so much effort and wasted thread. For me, the jury is still out on that one. Perhaps next time, I’ll dye more thread, risk losing them to sampling, and actually sample first. We’ll see…

Finished! It took a little over a year to go from concept, plant seeds, purchase materials, finish the design, gather the dye product, wind the warp, natural dye the warp and then paint the warp, weave, wet finish, sew and press! From seed to tablecloth with an eye towards natural products, this was an incredibly satisfying journey and project. I look forward to pushing the bar closer to a more fully “natural” experience.