Project Dates: 12/18/2018 - 1/3/2021

This adventure started with a holiday present of the book "250 Japanese Knitting Stitches" by Hitomi Shida for the December 2018 holiday season. Next came a trip to the yarn store for a March birthday. I spent a lot of time touching, testing colors and textures against each other during that yarn buying adventure. I had no pattern, just the vague notion of a large bedspread. This was and is this fiber enthusiast’s Nirvana! The basket of yarn grew until it looked like it would be enough to make something to cover a king size bed. The colors were in various shades of purple, green, blue, with rust and peach to add energy.

The design target idea morphed over time. Originally it was going to be simply a conglomeration of different size knitted squares pieced together, sort of a modern take on a 1950’s mod esthetic. It was going to be an afghan large enough to cover the bed which eventually turned into a sewn quilt with stuffing and backing. The end results incorporated knitted squares and rectangles appliquéd over grey flannel, and topped off with a combination of hand and machine quilting. And, of course, it just demanded to have matching pillow shams.

The design target idea morphed over time. Originally it was going to be simply a conglomeration of different size knitted squares pieced together, sort of a modern take on a 1950’s mod esthetic. It was going to be an afghan large enough to cover the bed which eventually turned into a sewn quilt with stuffing and backing. The end results incorporated knitted squares and rectangles appliquéd over grey flannel, and topped off with a combination of hand and machine quilting. And, of course, it just demanded to have matching pillow shams.

This journey of the “make” starts with a habit. Every morning upon waking, the very first priority after ablutions is coffee and fiber. My husband and I get up very early to watch the sun rise. While enjoying coffee, we have mild conversation and I enjoy the waking up process by making something with fiber. Sometimes it’s knitted. Other times crochet. I have been known to do cross stitch. But it is always something using fiber. I start my day in the energy where I desire most to spend my life…my partner and my fiber enthusiasm!

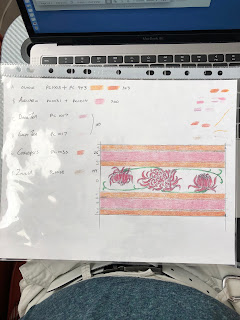

I designed a mod art grid of various rectangles and squares. Gave them each a target measurement and then perused the Hitomi pattern book! I measured the wraps per inch (WPI) for each of the yarns. They turned out to all be within the same small range except for one. Two swatch samples were knitted for each representative WPI group. This was an analytical nerd’s dream. Armed with the knitting gauge from the swatches, the block and color design, the target size for each square and rectangle, I then proceeded to allocate the yarns to each color block. I methodically analyzed the amount of yardage for each square and matched the overall pattern to the amount of yarn available which sometimes required moving blocks of colored squares around. This was a puzzle maker’s dream!

Next came the hunting expedition to come up with a series of Hitomi patterns that I thought worked well together. Each square was to be a different pattern. I ended up with fourteen different knitting patterns. Each square had to be designed separately. Though I had an overall pattern, the specific size of the square and the pattern repeats all had to be figured out. That was a fun exercise! I did this as I went. For each square, after coming up with the design, I documented the start and finish, tracked the rows, knitted and bound off, wet finished, laid each square out and pinned to size to dry. They collected themselves in a cardboard box awaiting their next incarnation! This whole exercise of squares, pattern design, and knitting lasted over seven glorious months. The completion of each square intrigued my creative self. The pattern mixed with the color and type of yarn was a fascinating experience to watch unfold.

Just about the time this was being completed it was time to move again, plus the new house needed some renovation. Morning coffee and fiber continued but in other, more mobile projects. The next steps in this project required longer blocks of time which meant that I needed weekends.

During the house renovation these blocks of time were unavailable for fiber art, so this project got put on hold for about eight months from about February 2020 until October 2020. It was at this time that the idea morphed from a pieced afghan to a quilt. The lightness of the squares and the intended size didn’t seem like they would hold up well. The mod look of the squares would be lost. Applying the squares to a backing to showcase them properly seemed the way to go. Plus I could exercise yet two more crafts: quilting and sewing!

To bring out the color of the yarn squares, I chose a gray flannel. My husband suggested metallic thread for the quilting which I opposed at first. However, he is an artist in his own right, so his experience is valued. I relented and tried out the metallic thread, which turned out wonderfully to my eyes! I ended up by using the metallic version of all the same yarn colors. Each of the metallic threads were used in the same area as the colored squares which nicely pulled the design together.

The process of placing the squares onto a king size quilt was rather arduous! On the cleaned wood floor my poor old knees went. I opted to pin baste. The target size of the squares and the end results, given the knitted aspect of the fabric, forced a few small redesigns on square placement. Basically, I ended up with three blank squares. In these I created quilting designs using an oak leaf, branch, and chestnut motif.

After all this pin basting, then came appliqueing the squares to the top layer of flannel fabric. I was able to do all of that using various colored metallic threads and a new sewing machine. Even with just one layer, it required some effort to handle and manage the amount of fabric.

After a few weeks of that fun, it was back on the wood floor, on my aching knees to pin the lower layer, the cotton batting, and the appliqued top layer together to form the quilt proper. Carefully rolling each end to the middle, I carried this surprisingly very heavy bundle and approached the sewing machine. Uh, it was like David and Goliath meeting. The intent was to quilt from the middle out as is customary. Let’s just say, there was no way a rolled-up king size quilt, even just one half of it, was going to fit through that unbelievably tiny area between the sewing needle arm and the machine proper. What to do. Well, hand sewing it is. I spent several weeks hand quilting and outlining each square and even within the squares to not only complete the design, but to hold the batting sandwich in place like a good quilt should!

Two more steps to go! Next came quilting the all-over quilting around the outside edges. All around the quilt was a space about eighteen inches that needed to be quilted. I chose a combination of straight lines and stippling. Stippling creates a visual affect much like wind blowing over water, except rather than circular waves, it looks more like spaghetti dropped from a height! For those of us who like structure and order, trying to do a freeform stippling affect, while maintaining somewhat regular spacing but with irregular design, seems like a task for a superperson! I can follow lines. But to arbitrarily move the quilt around to create a random pattern was strenuous to say the least. It was an exercise in letting go! Yikes!

Each of the blank squares that I mentioned earlier that received the oak leaf pattern was done with pinning a paper pattern and machine quilting over the top of that. I chose that over trying to transfer the design to the fabric. But, that required a very time-consuming exercise, or should I say meditative exercise with small scissor tweezers to pull the paper pattern off the quilt, bit by miniscule bit! I did that in between the long wait times that dyeing entails which was a process that was occurring simultaneously on another project.

We finally made it to the final step, the binding. By comparison that was fun and easy. It was machine sewn on one side, and then handstitched all round on the other side. It was done in a purple that matched the purple yarns, and pulled the entire project together.

All of the above was tested first on the pillow shams which served as a sort of sampling exercise. The only difference was that the entire pillow shams were machine quilted. There was no issue with squeezing the shams under the sewing arm. I didn’t discover that until I tried with the king size quilt itself.

This was a very labor-intensive experience, but one fun adventure!

Enjoy!